The Impact of 3D Printing on Boat Building and Its Insurance Considerations

January 9, 2025

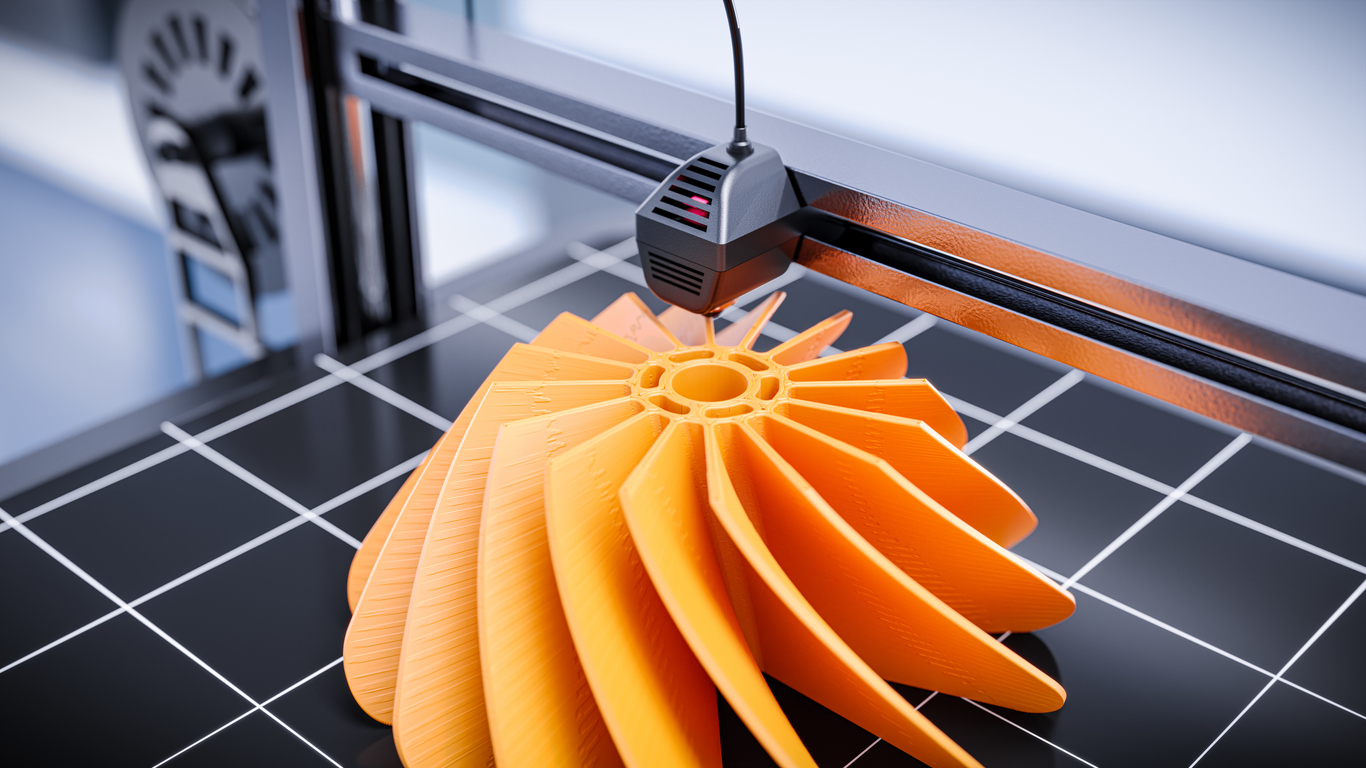

As boat builder insurance evolves with technological advancements, the growing impact of 3D printing is reshaping the boat-building industry. Along with other new technologies, boat builders are leveraging 3D printing to streamline production and enhance design flexibility.

The adoption of 3D printing is revolutionizing boat design and construction by allowing for more precise, custom-built components and faster production times. As this technology transforms the industry, boat builders must consider new insurance implications to address the evolving risks and challenges involved.

The Rise of 3D Printing in Boat Building

Using 3D printing for boat parts offers several advantages that improve both production efficiency and design flexibility.

- Cost reduction: 3D printing minimizes material waste and lowers labor costs by streamlining production processes, leading to overall savings.

- Customization: This technology allows boat builders to create highly customized parts tailored to specific needs, enhancing the uniqueness and performance of each boat.

- Speed: 3D printing accelerates the manufacturing process, enabling quicker turnaround times for both prototypes and final products.

- Reduced inventory: On-demand production eliminates the need to maintain large stockpiles of parts, cutting storage costs and reducing the risk of overproduction.

- Complexity in design: With 3D printing, boat builders can produce complex, intricate parts that would be difficult or expensive to make using traditional methods.

Custom boat makers are adopting 3D printing to create unique, tailored designs for individual clients. Manufacturers of smaller boat parts also benefit from this technology, as it enables efficient production of specialized components.

Key Risks Introduced by 3D Printing

While 3D printing offers significant advantages, there are several potential risks that boat builders must consider.

- Durability and longevity: 3D printed materials may not always meet the long-term durability standards required for boats, particularly in harsh marine environments.

- Quality control: Maintaining consistent quality in 3D printed parts requires careful monitoring and thorough inspections, as discrepancies in the printing process can affect performance.

- Intellectual property liability: Boat builders may face patent infringement risks if the designs they print are based on protected intellectual property, potentially leading to legal challenges.

How Boat Builder Insurance Is Adapting

As the boat-building industry adapts to the growing use of 3D printing, boat-builder insurance policies are evolving to address the unique risks associated with this technology.

- Product liability for 3D printed boat parts: Insurance policies are increasingly offering coverage for defects in 3D printed parts that could lead to accidents or damage, protecting builders from liability claims.

- Coverage for intellectual property disputes: Some policies include coverage for potential intellectual property conflicts, such as patent infringement, resulting from the use of 3D-printed designs.

- Adjustments in risk assessments: Insurers are modifying risk assessments to account for the use of advanced materials and printing techniques, which may introduce new challenges in terms of durability and performance.

Navigating the Future of Boat Building

Boatbuilder insurance needs to evolve alongside new technologies like 3D printing to support boat builders. Agents should stay informed about these advancements to provide tailored coverage that addresses the unique risks of 3D-printed components. Stay ahead of industry changes — call Merrimac Marine Insurance now!

About Merrimac Marine Insurance

At Merrimac Marine, we are dedicated to providing insurance for the marine industry to protect your clients’ businesses and assets. For more information about our products and programs, contact our specialists today at (800) 681-1998.